Product

Contact Us

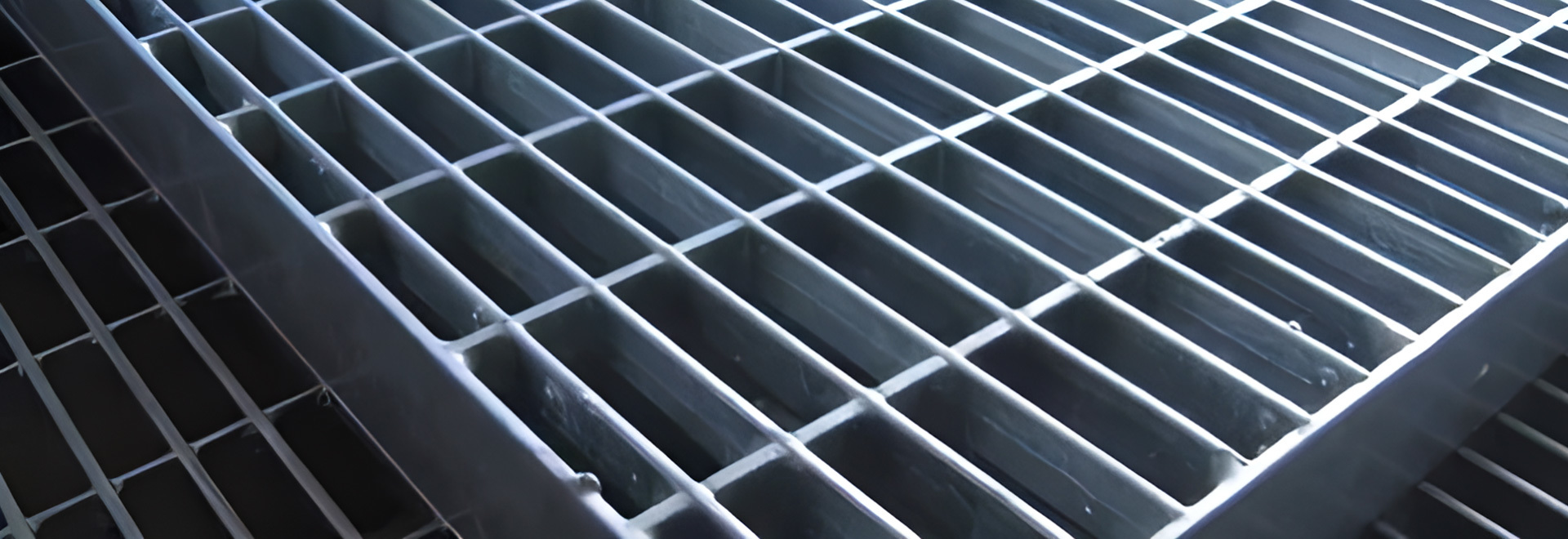

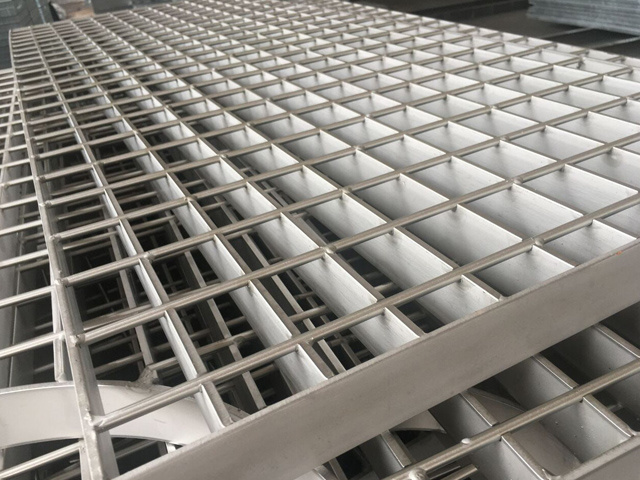

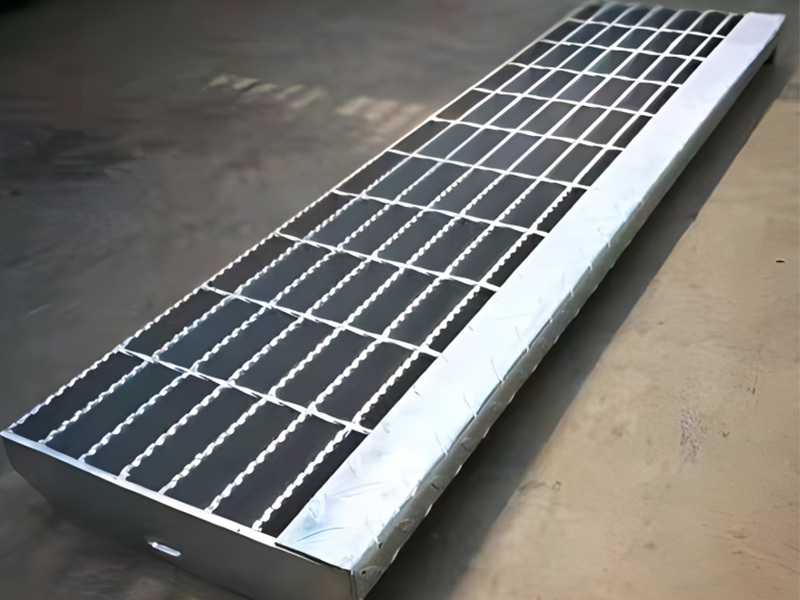

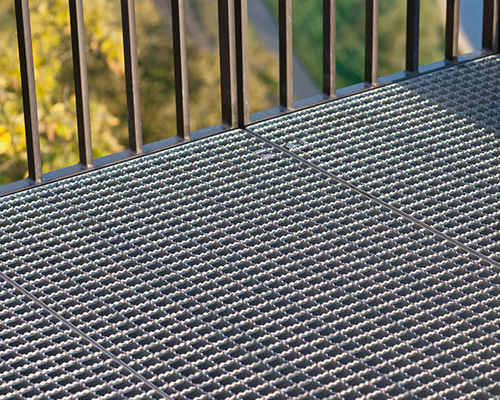

Galvanized Steel Grating

Product Details

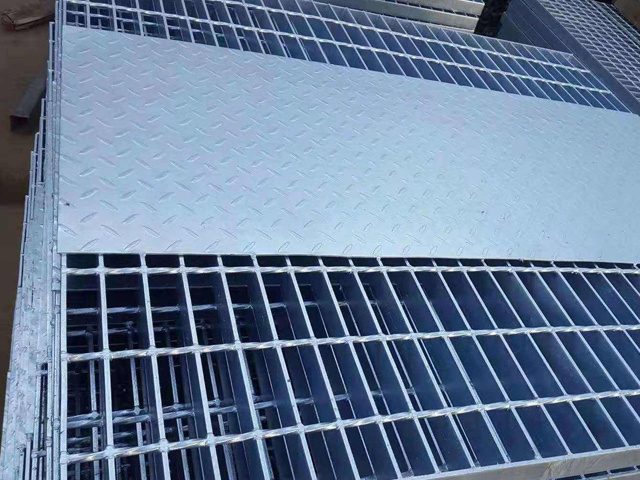

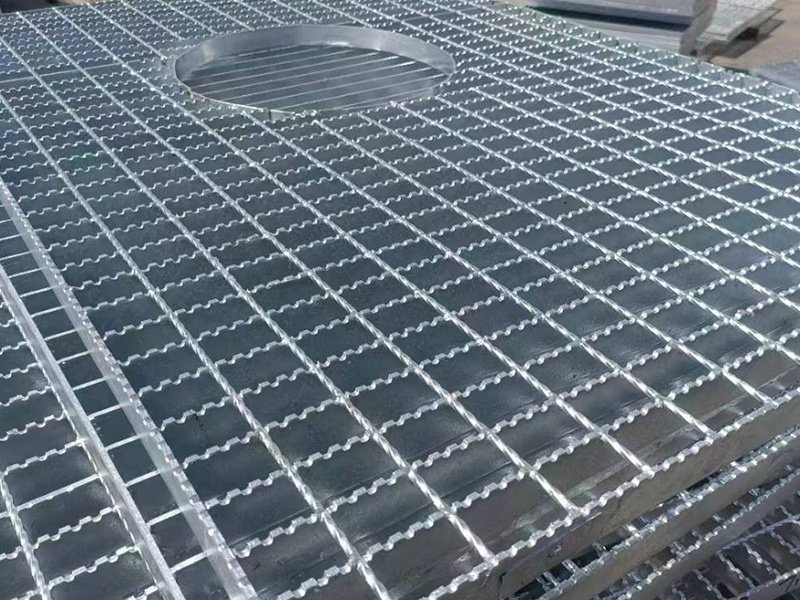

Galvanized steel grating is a versatile steel product formed by arranging loaded flat steel and cross bars at specific intervals in warp and weft. These components are welded together using a high-voltage resistance welding machine, creating the original plate. Further processing, including cutting, incision, hole opening, and edge wrapping, is done to meet customer requirements and produce the finished product.

Types of Galvanized Steel Grating:

Manufacturing Process: Galvanized steel grating can be categorized into pressure-welded and pressure-locked types based on the manufacturing method.

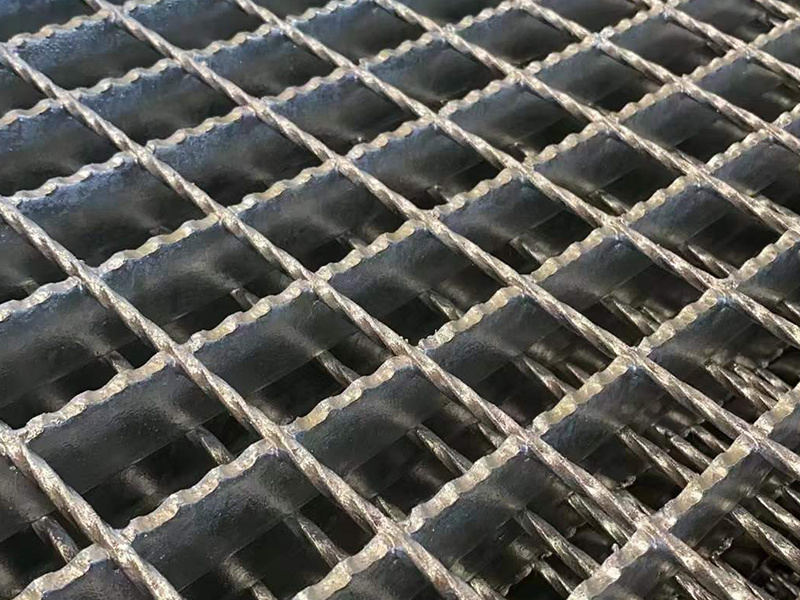

Surface Shape: Galvanized steel grating can be further divided into tooth-shaped, flat type, I-type, and composite type plates, depending on the surface shape.

Identification Method of Galvanized Steel Grating: (1) Flat Bar Center Distance: Differentiated by series: Series 1 has a center distance of 30mm; Series 2 has a center distance of 40mm; Series 3 has a center distance of 60mm. (2) Distance Between Centers of Crossbars: Series 1 has a distance of 100mm, and Series 2 has a distance of 50mm. Other specifications can be customized. (3) Flat Steel: Made of Q235A or stainless steel, with various types such as ordinary flat type, slip-resistant tooth type, and section I type. Common specifications include 205, 255, 253, 325, 405, 403, 505, 655, 756, 1008, 10010, and more. (4) Cross Bar: Made of round steel, twisted square steel, square steel, or hexagonal steel using Q235A or 304 stainless steel. Twisted square steel is made through wire drawing and twisting in a square die, with common specifications of 55, 66, 88mm, etc.

Features and Usages of Galvanized Steel Grating:

Features:

High Strength and Light Structure: The strong mesh pressure welding structure ensures high load-bearing capacity and a lightweight structure, making it easy to handle and install.

Durability and Aesthetics: Galvanized steel grating boasts a beautiful appearance and long-lasting performance.

Usages: Galvanized steel grating finds extensive applications in various industries and sectors, including:

Platforms, Walkways, and Trestles

Ditch Covers and Manhole Covers

Ladders and Fences

Petrochemical Plants, Power Plants, Water Plants, Sewage Treatment Plants

Municipal Engineering and Sanitation Engineering Projects

It serves as an essential product in these fields due to its strength, versatility, and reliability.

keyword:

Galvanized Steel Grating

Customer visits

Shipping photos

Quality Control

Our Advantages

Steel grating is a kind of economic, practical and beautiful steel structure plate, which is widely used in industrial plants, municipal engineering, roads and bridges, traffic facilities and other fields. As a professional steel grating manufacturer, we have the following corporate advantages:

Rich production experience:

we have many years of experience in the production of steel grating, skilled in all kinds of production processes and technical points, to ensure stable and reliable product quality.

Advanced production equipment:

we have introduced advanced production equipment and technology at home and abroad, which can produce high quality steel grating products in line with international standards.

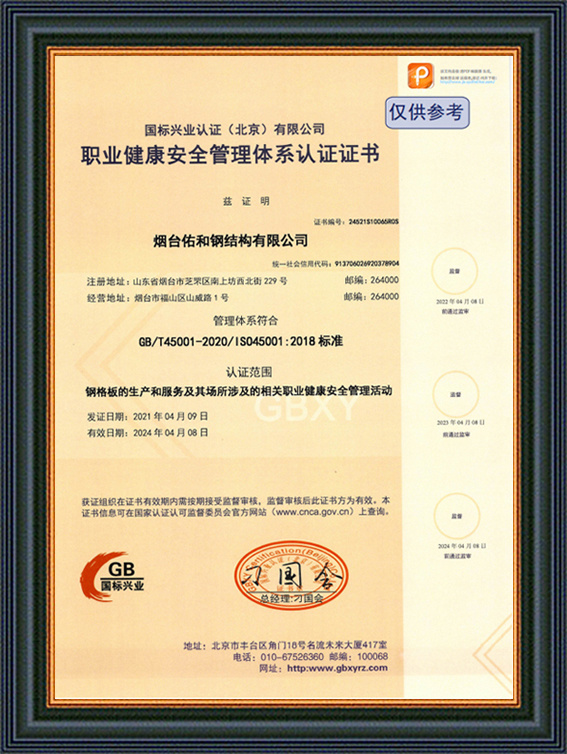

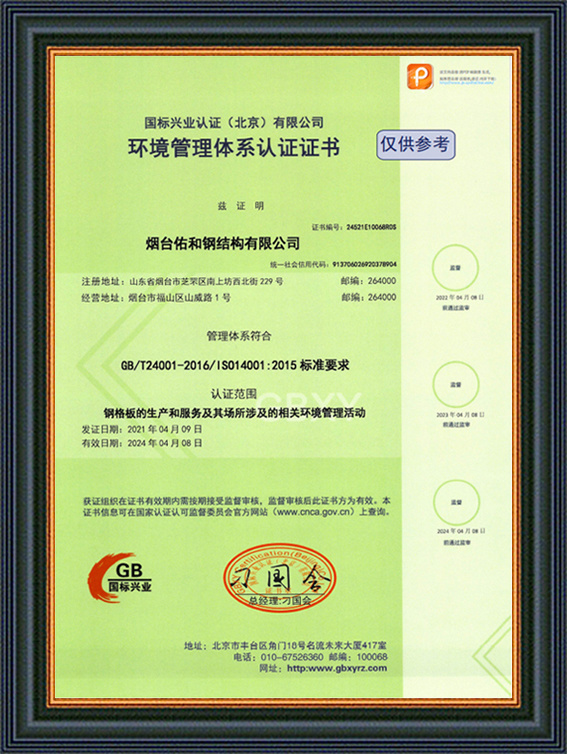

Perfect quality management system:

we have established a perfect quality management system and strictly implement ISO9001 quality management system to ensure stable and reliable product quality.

Diversified product specifications:

We produce steel grating with rich specifications, which can meet the needs of different customers, and we can also customise special specifications according to customers' requirements.

Competitive price:

We have our own production factory, which can directly control the production cost and ensure the competitive price.

Timely after-sales service:

we have established a perfect after-sales service system, which can deal with customers' complaints and problems in time to ensure customer satisfaction.

Good reputation and word of mouth:

Over the years, we have been adhering to the business philosophy of "honesty and trustworthiness, quality first, customer first", which has won the trust and praise of customers.

Project Cases

FAQ

What standards do your steel gratings meet?

We are able to manufacture steel gratings with standards in different countries, such as YB/T4001.1-2007, ANSI/NAAMM (MBG531), BS4592 and JJS Standards.

How do you control the quality of your gratings?

To ensure high quality, we use advanced production lines and inspection machines. We strictly follow manufacturing requirements and have numerous certifications.

What specifications and types do you supply?

We can produce steel gratings of any specifications or types. Just let us know your dimensions, materials, color, and other requirements, and we'll customize them for you. We ensure they meet your needs.

What’s your raw material?

What’s the difference between plain grating and serrated grating?

The serrated gratings have better anti-slip performance but come at a higher price compared to regular gratings. They are widely used in petrochemical engineering.

What’s the surface treatment?

The surface treatment includes hot-dip galvanization, painting, electrostatic coating or non-treatment.

What does length and width exactly refer to?

In a grating, the length means the length of bearing bar while width means the length of cross bar. When placing your order, please provide clear dimensions to avoid any potential errors.

How do you calculate the area of each grating?

a. For regular shape grating, the area equals to length multiplied by width of grating, including the area of holes and notches.

b. For irregular shape grating, the area is that of the steel grating before cutting, instead of the area of irregular shape grating.

Why should we offer the structure drawing and detailed parameters of the work site?

This is to better serve your needs. Based on your structure drawing and parameters, we design and offer a grating perfectly suits your work site and ensure no extra cutting while usage. It greatly simplifies the installation work and saves your time. What’s more, according to the information you offer, we can recommend you the best suitable grating, which will save you time and money. We can also avoid the confusion between length and width mentioned in Q7 and prevent unnecessary economic loss for you.

How do you control the quality of the products leaving the factory?

Related Products