Product

Contact Us

Stair Tread Steel Grating

Product Details

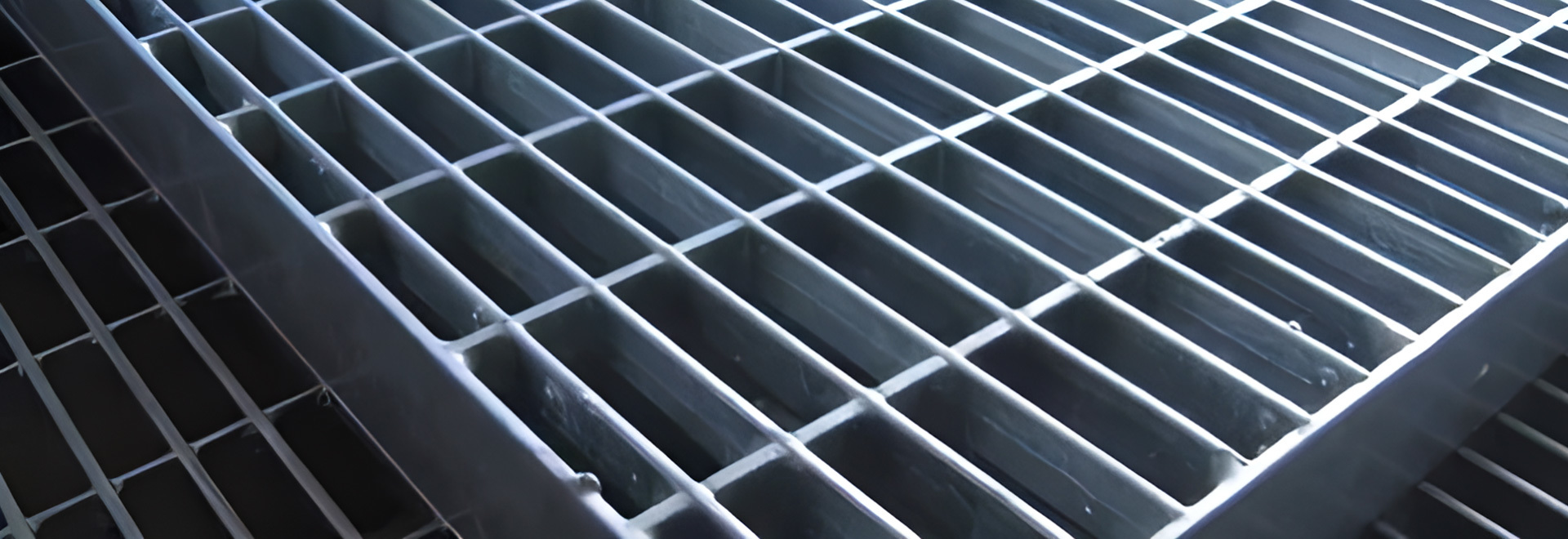

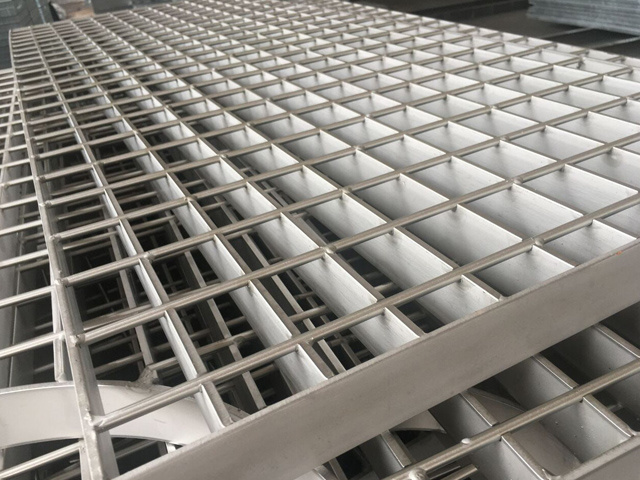

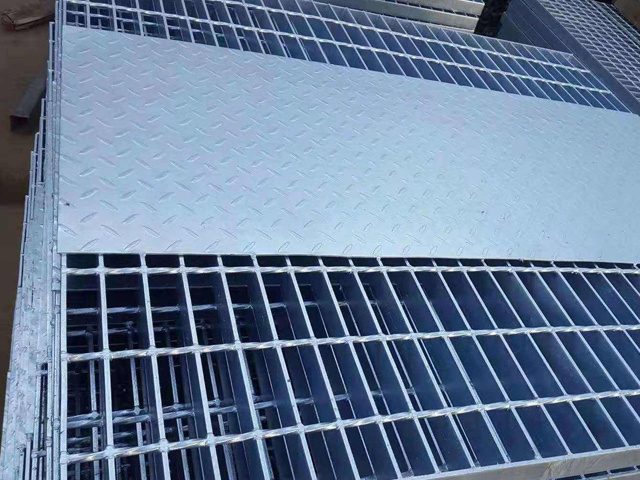

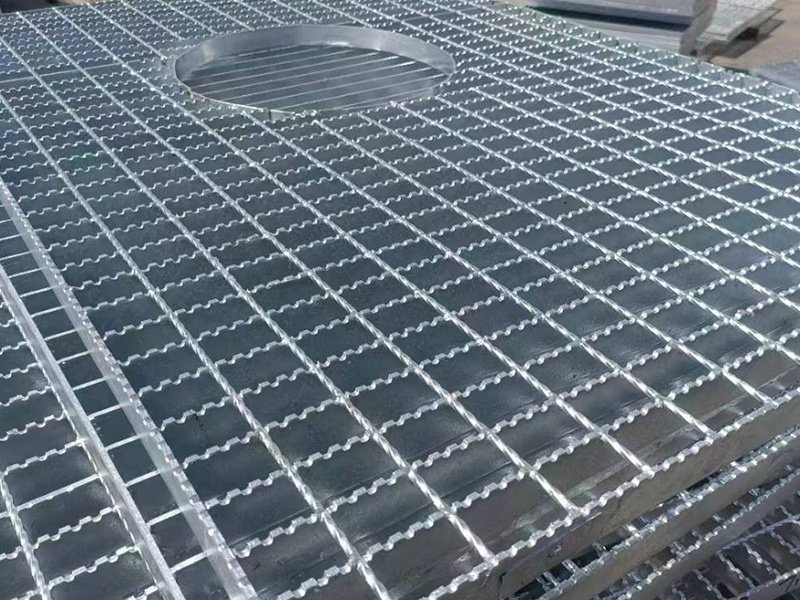

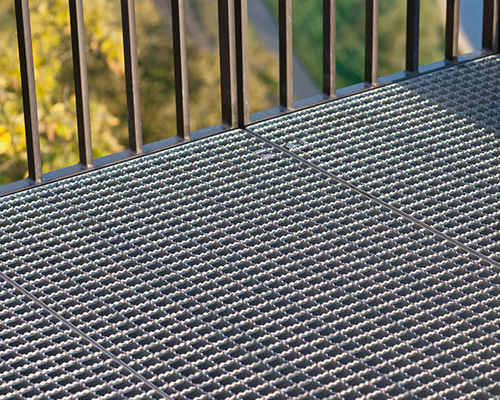

Stair Tread Steel Grating also known as steel grating treads, are made from cross-arranged flat steel bars and crossbars, welded into checkered plates. These steel grating treads are often surface-treated with hot-dip galvanization or electrogalvanization. They are an essential component for steel structure platforms and play a vital role in providing safe access up and down these platforms.

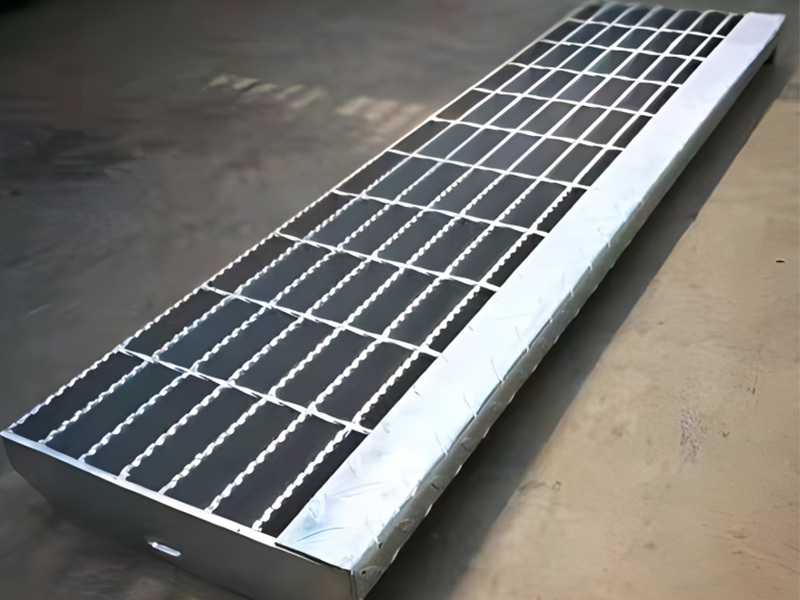

Stair Treads Models: Stair treads are categorized into different types: T1-type, T2-type, T3-type, and T4-type tread plates. The primary distinction lies in the presence of a front guard and perforated side panels, although customization is also possible.

To choose suitable treads, the following considerations can be made: Function and use area are essential factors. When there is high foot traffic on the stairs, it is advisable to opt for treads with a front guard plate for added safety. Alternatively, for cost-effectiveness, treads without a front guard plate can be chosen. Installation methods include bolting or welding. Bolted installation requires the addition of a perforated rear side plate, whereas direct welding eliminates the need for side plates. The production of treads should adhere to national steel ladder production standards. The surface treatment typically involves hot-dip galvanization or painting, with anti-rust paint applied before the topcoat to ensure long-term anti-corrosion protection.

Stair Steel Grating Installation Method: Stair steel grating can be installed using two methods: welding and bolting. For direct welding to the keel steel beam, side panels are not required, resulting in a cost-effective and durable solution, though less easy to disassemble. For bolt-fixed step plates, thicker side panels are necessary, and the installation is done using bolts, allowing for recycling and reusability. Customization is available, enabling the production of steel grating treads in various sizes to match specific stairs. However, it is recommended to consider standard sizes for economic efficiency.

Specifications of Stair Steel Grating: Stair treads can be produced with different anti-slip front guards, and the size can be specified as needed.

Width options: 700mm, 800mm, 900mm, with a minimum width of 600mm. The maximum width is ideally no more than 1200mm. For stairs with single passage, the width between two inclined beams or guardrails should not be less than 600mm.

When stairs frequently experience multiple people crossing at the same time or are designated as evacuation routes, the ladder width should be increased to 1200mm.

The protruding edge of the stair tread should bear a load of 1.5KN. For widths up to 1200mm, the load acts on an area of 100mm×100mm, and the deflection of the treads should not exceed 1/500 of the span of the stairs.

The overlapping part of the vertical projection of two adjacent upper and lower stair treads should not be less than 10mm.

Usage of Stair Steel Grating: Stair treads find wide-ranging applications in various industries, including power plants, water plants, municipal engineering, sanitation engineering, theaters, viewing platforms, and parking lots, where they serve as essential platforms and walkways, providing safety and functionality.

keyword:

Stair Tread Steel Grating

Customer visits

Shipping photos

Quality Control

Our Advantages

Steel grating is a kind of economic, practical and beautiful steel structure plate, which is widely used in industrial plants, municipal engineering, roads and bridges, traffic facilities and other fields. As a professional steel grating manufacturer, we have the following corporate advantages:

Rich production experience:

we have many years of experience in the production of steel grating, skilled in all kinds of production processes and technical points, to ensure stable and reliable product quality.

Advanced production equipment:

we have introduced advanced production equipment and technology at home and abroad, which can produce high quality steel grating products in line with international standards.

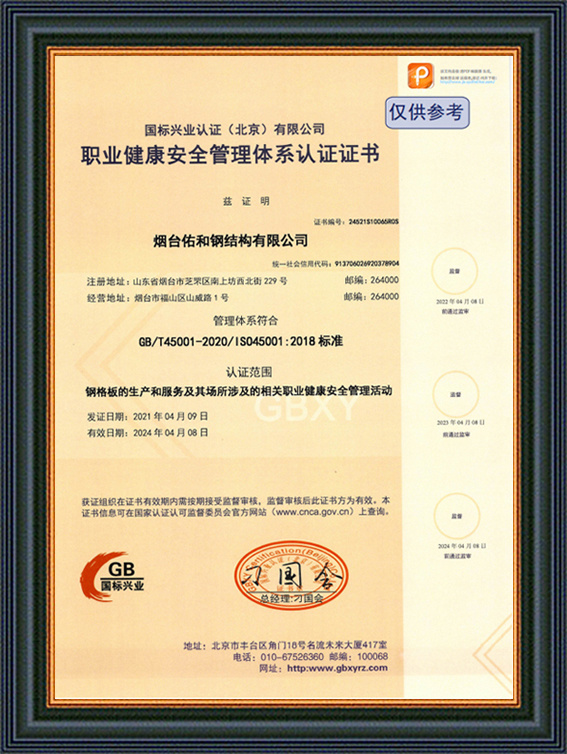

Perfect quality management system:

we have established a perfect quality management system and strictly implement ISO9001 quality management system to ensure stable and reliable product quality.

Diversified product specifications:

We produce steel grating with rich specifications, which can meet the needs of different customers, and we can also customise special specifications according to customers' requirements.

Competitive price:

We have our own production factory, which can directly control the production cost and ensure the competitive price.

Timely after-sales service:

we have established a perfect after-sales service system, which can deal with customers' complaints and problems in time to ensure customer satisfaction.

Good reputation and word of mouth:

Over the years, we have been adhering to the business philosophy of "honesty and trustworthiness, quality first, customer first", which has won the trust and praise of customers.

Project Cases

FAQ

What standards do your steel gratings meet?

We are able to manufacture steel gratings with standards in different countries, such as YB/T4001.1-2007, ANSI/NAAMM (MBG531), BS4592 and JJS Standards.

How do you control the quality of your gratings?

To ensure high quality, we use advanced production lines and inspection machines. We strictly follow manufacturing requirements and have numerous certifications.

What specifications and types do you supply?

We can produce steel gratings of any specifications or types. Just let us know your dimensions, materials, color, and other requirements, and we'll customize them for you. We ensure they meet your needs.

What’s your raw material?

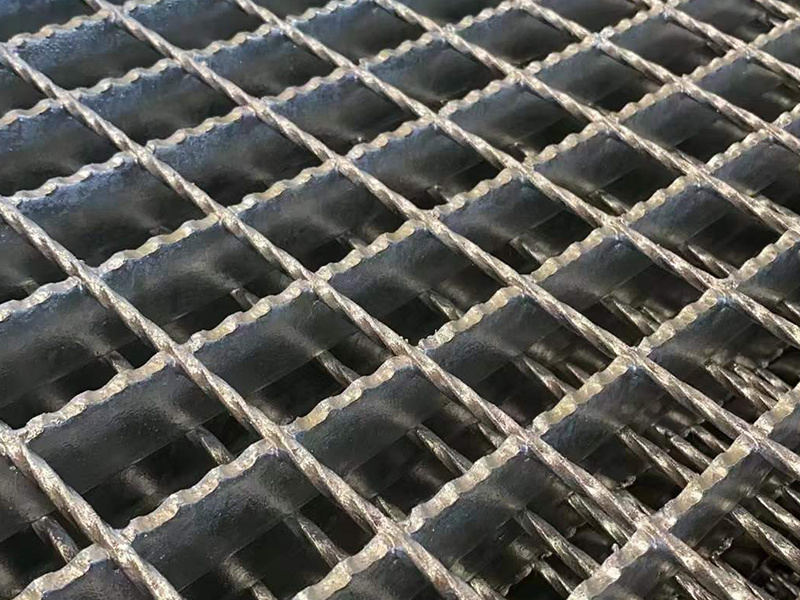

What’s the difference between plain grating and serrated grating?

The serrated gratings have better anti-slip performance but come at a higher price compared to regular gratings. They are widely used in petrochemical engineering.

What’s the surface treatment?

The surface treatment includes hot-dip galvanization, painting, electrostatic coating or non-treatment.

What does length and width exactly refer to?

In a grating, the length means the length of bearing bar while width means the length of cross bar. When placing your order, please provide clear dimensions to avoid any potential errors.

How do you calculate the area of each grating?

a. For regular shape grating, the area equals to length multiplied by width of grating, including the area of holes and notches.

b. For irregular shape grating, the area is that of the steel grating before cutting, instead of the area of irregular shape grating.

Why should we offer the structure drawing and detailed parameters of the work site?

This is to better serve your needs. Based on your structure drawing and parameters, we design and offer a grating perfectly suits your work site and ensure no extra cutting while usage. It greatly simplifies the installation work and saves your time. What’s more, according to the information you offer, we can recommend you the best suitable grating, which will save you time and money. We can also avoid the confusion between length and width mentioned in Q7 and prevent unnecessary economic loss for you.

How do you control the quality of the products leaving the factory?

Related Products